Tennessee is home to several of the nation’s leading manufacturing firms, helping to make the state’s manufacturing sector the second-largest contributor to both GDP and employment. The industry generates over $70 billion in manufacturing value-added output – about 14.8% of the state’s GDP – and employs 362,480 residents, representing 12.7% of all private sector jobs.

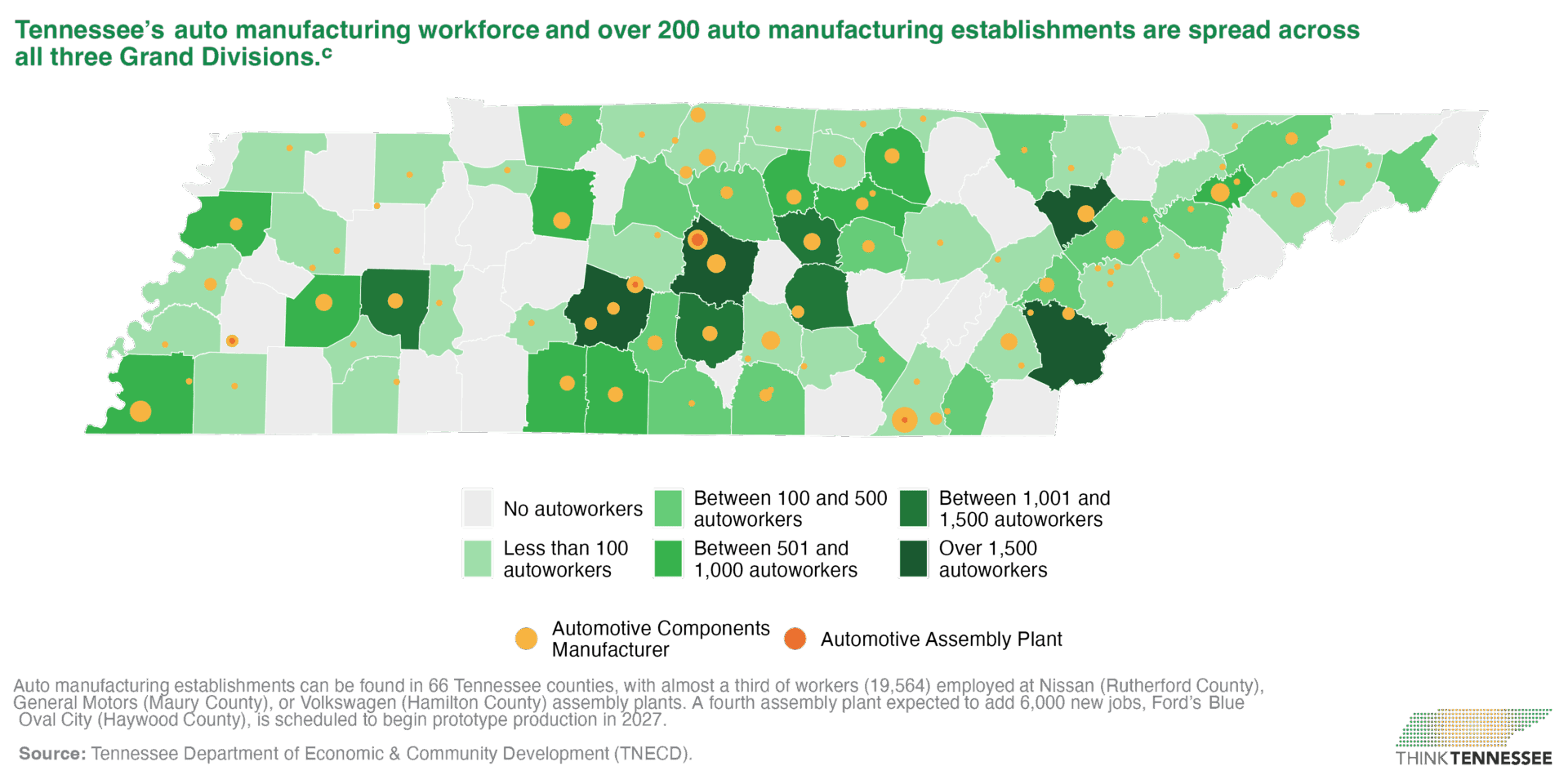

Auto manufacturing accounts for 16.6% of the state’s manufacturing output and employs 18.4% of the manufacturing workforce – Tennessee has the third-highest number of auto manufacturing jobs in the nation. Having grown significantly since its emergence in 1983, growth is expected to continue with projections to reach 86,459 workers in 2032. In part, this growth reflects $16.6 billion in announced EV investments and an expected 18,300 new jobs – positioning Tennessee to be a national leader in EV manufacturing. [a],[b]

To meet the momentum, Tennessee must address a critical workforce training gap through strategic investments in preparing the state’s workforce for these high-skill, high-paying jobs.

Key Takeaways

- Tennessee’s auto manufacturing industry has grown significantly, outpacing growth in the manufacturing sector as a whole in output, size, and workforce. [jump]

- The auto manufacturing industry provides competitive wages and benefits and offers substantial growth potential. [jump]

- Auto manufacturing jobs are expected to continue to grow by an average of 2.6% annually from 2022 to 2032. Workforce training initiatives must meet the anticipated labor demand. [jump]

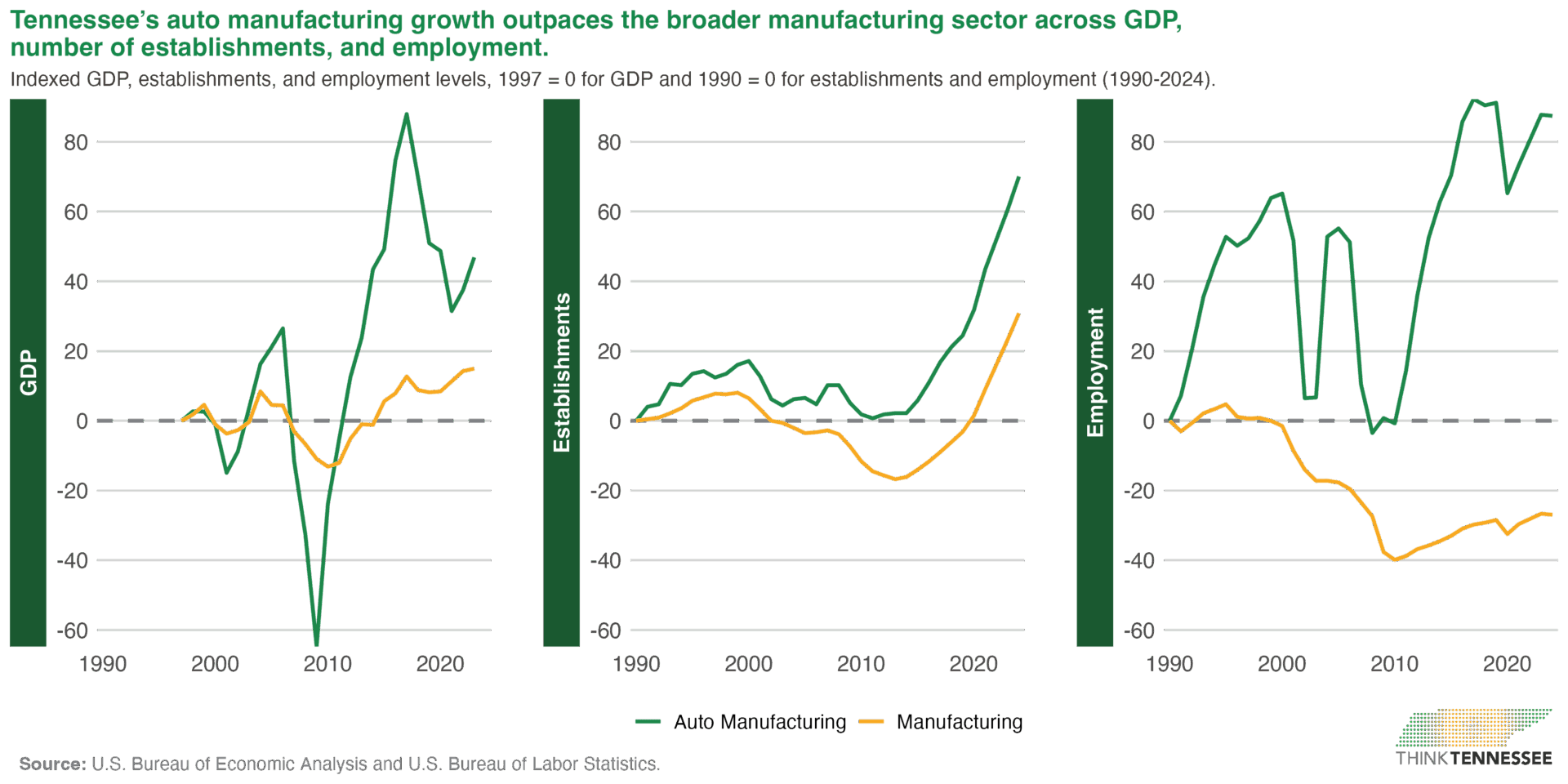

Tennessee’s auto manufacturing industry has grown significantly, outpacing growth in the manufacturing sector as a whole in output, size, and workforce.

Auto manufacturing output (GDP) increased 1.5% on average each year from $7.9 billion in 1997 to $11.6 billion in 2023 – three times the 0.5% growth rate of the manufacturing sector as a whole.[d]

Since 1990, the number of auto manufacturing establishments increased 1.6% annually (double the manufacturing sector’s 0.8% growth rate), and the workforce increased at an annual rate of 1.9%, reaching 66,828 employees in 2024 – faster than the -0.9% of the manufacturing sector and the 1.3% of the total private industry sector.

Tennessee’s auto manufacturing industry provides competitive wages and benefits and offers substantial growth potential.

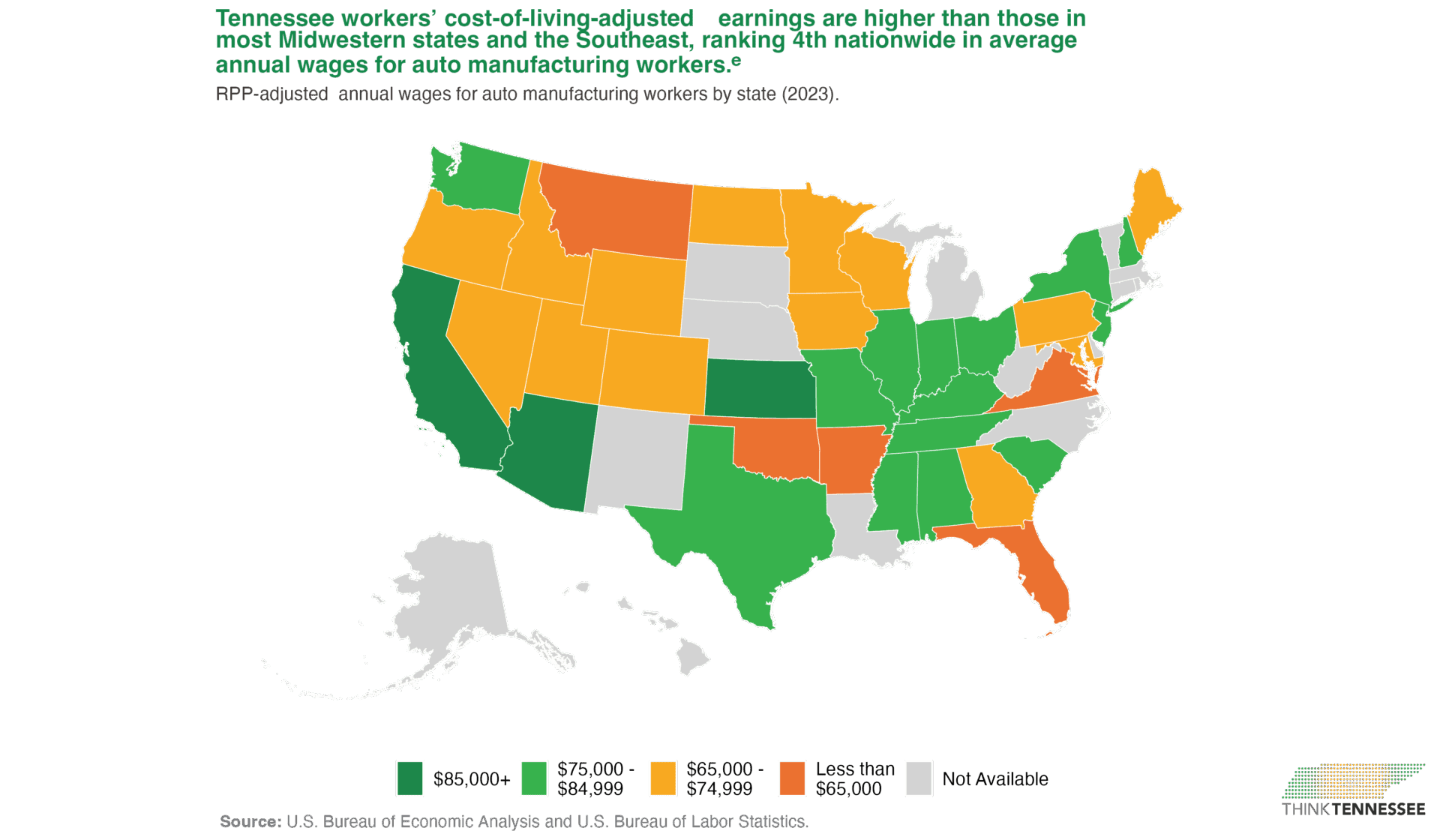

Auto manufacturing workers in Tennessee earn more on average than others nationally and other industries in the state.

With average annual earnings of $76,194, Tennessee’s auto manufacturing workers earn more than others in the manufacturing sector ($74,852) and in the private sector ($68,763). Annual wages are higher than the state average in eight counties, with workers in Jefferson, Williamson, and Rutherford earning over $100,000.

While the auto manufacturing industry’s competitive salaries exceed the cost of living of single-member households ($43,683) and of single-parent families with one child ($64,718), their purchasing power has remained stagnant.[f],[g],[h] Since 1999, workers have seen just 0.2% annual wage increases when adjusted for inflation, three times lower than the 0.6% rate of workers across Tennessee’s private sector.

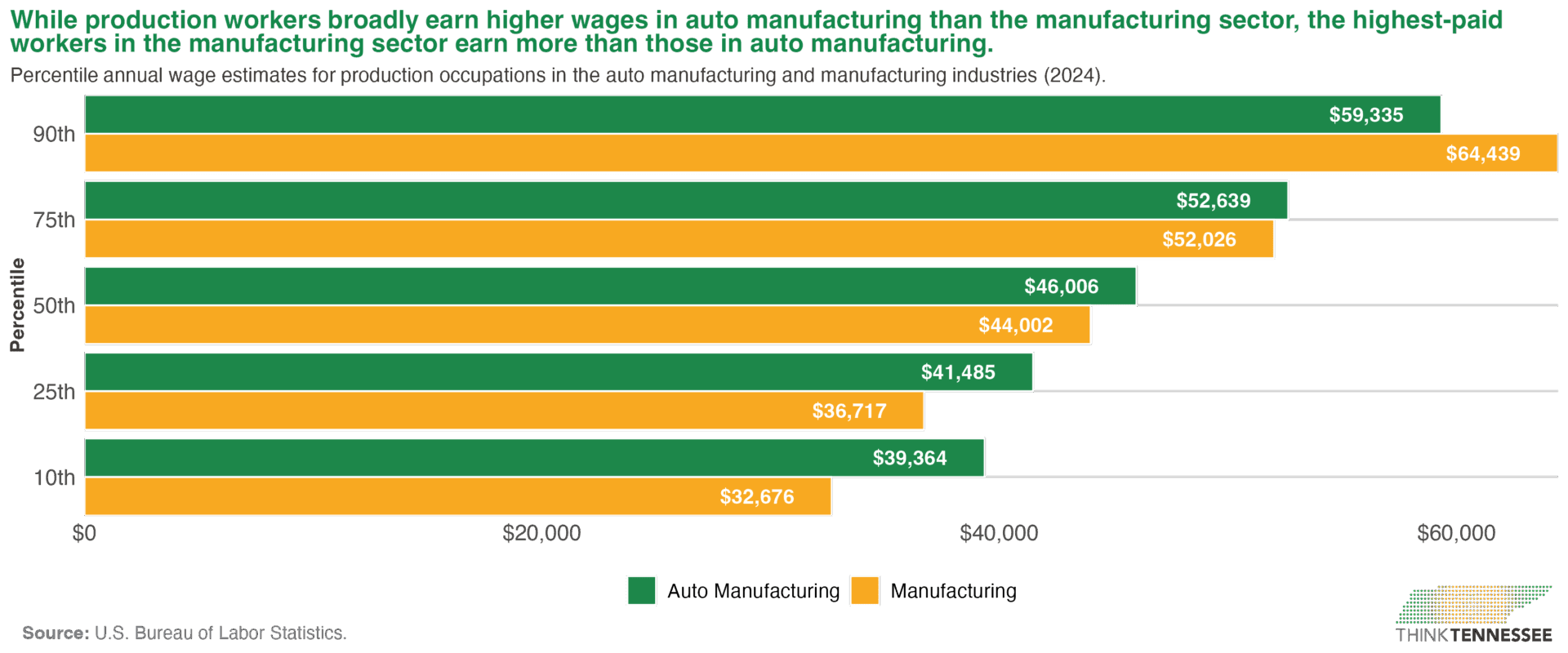

The auto manufacturing industry offers substantial growth potential, with earnings outpacing the broader manufacturing sector in early- to mid- career levels.

Most production occupations (66.9% of Tennessee’s auto manufacturing workforce) require no more than a high school diploma at the entry level. Entry-level workers can expect to start with annual wages below $40,000 and can advance to median earnings of around $47,000 mid-career, with highly experienced autoworkers earning over $57,000.[i] EV manufacturing positions are estimated to earn higher wages – $40,745 to $43,601 at entry level, reaching $46,896 mid-career, and those requiring advanced education, i.e., electrical engineers, earning approximate median wages of $78,903.[j]

Degree and certificate completion remain key pathways to employment opportunities and higher wages. A majority (83%) of Tennessee technical and community college graduates of auto manufacturing-related programs find employment within their first year and earn a median wage of $51,415. Median wages increase 19.7% by their fifth year, climbing to $61,689.[k],[l],[m]

Tennessee’s auto manufacturing firms spend on average 10.1% more on worker’s benefits than those of other manufacturing industries.

Automotive firms spend $19,899 per worker annually on fringe benefits, which include $8,980 on health insurance, $3,077 on benefit pension and contributions plans, and $7,842 on other benefits. Comparatively, Tennessee ranks 13th among 43 states in auto manufacturing worker benefits with others in the Southeast spending more per worker, including West Virginia ($32,452), South Carolina ($25,641), North Carolina ($21,283), and Alabama ($19,990).[n],[o]

Anticipated growth in the auto manufacturing industry will need expanded workforce readiness.

Tennessee’s auto manufacturing industry is projected to increase by an average of 2.6% annually from 2022 to 2032. Already seeing just 0.42 candidates per available production job opening, Tennessee will need more workers to meet this growing demand.[p]

More graduates and training programs will help address workforce shortages. Between 2020 and 2023, only 2,043 students completed post-secondary production occupation certificates across 36 institutions, while another 9,890 received certificates during high school.

Additional training opportunities are increasingly coming through partnerships with auto manufacturers and their surrounding communities.

Tennessee’s ECD has announced partnerships with EV manufacturers to identify workforce skill needs, and with gas engine parts manufacturers to incentivize employee retraining. Manufacturers are also investing in training opportunities:

- Volkswagen’s $22 million Battery Engineering Lab (BEL) investment develops EV battery expertise in the region. They have also partnered with Chattanooga State Community College to offer an electrical engineering associate’s degree, creating a direct pipeline from education to employment.

- In June 2024, a new Tennessee College of Applied Technology (TCAT) opened at Stanton’s Blue Oval site, training individuals in EV manufacturing and battery plant operations.

- Through a public-private partnership between Nissan and the College System of Tennessee, a Nissan Training Center at the Smyrna TCAT campus provides both college-level and EV technology training to Nissan employees and TCAT students.

Matching ambition with action is Tennessee’s workforce imperative.

Tennessee stands at a critical juncture where investments in auto manufacturing must be matched by equally ambitious workforce development initiatives and competitive wages. The state’s success in leading the nation’s transition to automotive electrification depends on expanding training capacity, fostering deeper industry partnerships, and ensuring equitable access to opportunities across all communities.

Endnotes

[a] All dollar values are presented in 2023-adjusted dollars using the Consumer Price Index for All Urban Consumers (CPI-U) annual averages.

[b] The auto manufacturing industry comprises the North American Industry Classification System (NAICS) codes 3361 Motor Vehicle Manufacturing, 3362 Motor Vehicle Body and Trailer Manufacturing, and 3363 Motor Vehicle Parts Manufacturing.

[c] The size of the dots accounts for the number of establishments within each category that exist in each area, which ranges from 1 to 14 in Hamilton and Rutherford counties.

[d] Unless otherwise noted, all percentage changes are produced using the Compound Annual Growth Rate formula:

CAGR = ((Ending Value / Beginning Value)^(1 / Number of Years)) – 1.

[e] Annual earnings are adjusted for cost-of-living-differences across states using the Bureau of Economic Analysis’ Regional Price Parities (RPP) by State data for 2023.

[f] Annual earnings are based on the author’s analysis of the Bureau of Labor Statistics’ Quarterly Workforce Indicators (QWI) data for 2023.

[g] Auto manufacturing workers earn annual wages higher than the state average in Jefferson ($134,485.4), Williamson ($105,430.6), Rutherford ($101,967.0), Washington ($93,485.3), Maury ($87,491.2), Blount ($82,097.0), Sevier ($78,161.8), and Hamilton ($77,546.4) counties.

[h] Tennessee’s cost of living results from county-level values collected from the Economic Policy Institute’s 2024 Family Budget Calculator, and weighted by county population estimates from the U.S. Census Bureau.

[i] We associate early-career earnings with occupational wages at the 10th and 25th percentile, mid-career professionals with the median wage, and highly experienced professionals with the 75th to 90th percentile. Occupational wages are based on the author’s analysis of the Bureau of Labor Statistics’ Occupational Employment and Wage Statistics (OEWS) Research Estimates by State and Industry data for 2024.

[j] Starting wages represent the weighted average of the 10th and 25th percentile wages in electric vehicle manufacturing-related occupations within the auto-manufacturing industry codes. Averages are weighted based on number of employees in a given industry.

The identified electric vehicle manufacturing-related occupations are Software Developers (15-1252), Electrical Engineers (17-2070 and 17-2071), Chemical Engineers (17-2040), Chemical Technicians (19-4031), Electrical, Electronic, and Electromechanical Assemblers, Except Coil Winders, Tapers, and Finishers (51-2028), and Miscellaneous Assemblers and Fabricators (51-2090). There is no data associated with the Software Development occupation within the auto manufacturing industry in Tennessee.

[k] Inflation-adjusted median annual wages were identified from the Tennessee Board of Regents’ Careers Start Here Dashboard for employed graduates in auto manufacturing industries, including: Automobile and Light Duty Motor Vehicle Manufacturing (33611), Automobile Manufacturing (336111), Motor Vehicle Body Manufacturing (336211), Truck Trailer Manufacturing (336212), Travel Trailer and Camper Manufacturing (336214), Other Motor Vehicle Parts Manufacturing (336390), Motor Vehicle Gasoline Engine and Engine Parts Manufacturing (33631), Motor Vehicle Electrical and Electronic Equipment Manufacturing (33632), Motor Vehicle Steering and Suspension Components (except Spring) Manufacturing (33633) Motor Vehicle Brake System Manufacturing (33634), Motor Vehicle Seating and Interior Trim Manufacturing (33636), Motor Vehicle Transmission and Power Train Parts Manufacturing (33635).

[l] Employment rate was identified from the Tennessee Board of Regents’ Careers Start Here Dashboard for individuals who earned awards in their respective programs between 2013 and 2024. Auto manufacturing-related programs are identified based on the Tennessee Department of Economic & Community Development Center for Economy Research in Tennessee’s July 2024 Automotive White Paper. The programs included are: Mechanical Engineering Technology, Manufacturing Engineering Technology, Electromechanical Technology, Industrial Technology, Machine Tool Technology, Tool & Die Technology, Electrical Equipment Installation & Repair Technology, Industrial Electronics Technology, and Welding Technology.

[m] Percentage change represents the raw percentage change between inflation-adjusted median annual wages at the first- and fifth-year post-completion of workforce programs.

[n] Fringe benefits include all programs required under Federal and State legislation – including Social Security, unemployment insurance, workers’ compensation, and state disability payments, and voluntary employer-provided benefits – such as health and life insurance premiums, profit-sharing plans, and pension contributions for both qualified and non-qualified retirement plans.

[o] Inflation-adjusted firm expenditures on fringe benefits were extracted from the U.S. Census Bureau 2022 Economic Census, divided by the number of employees in a given industry.

[p] Jobs4TN.gov job openings advertised online and well as potential candidates in the workforce system in Tennessee the Production occupational group on August 18, 2025. Currently, the state has 1,303 potential candidates in Tennessee’s workforce system for 3,096 production job openings.